FROM SHEEP TO RUG

WOOL

FACTORS THAT DETERMINE & INSURE QUALITY:

- SPECIAL BREED -

- Out of 952 breeds of sheep - only a select few qualify to meet the quality

requirements of the wool used in the production of fine rugs.

- PROPER RAISING OF SHEEP -

-

A special diet as well as optimal climate and altitude are provided as essential factors

influencing the quality of the wool.

- The age of the sheep as well as the time of the year shearing occurs are additional

important factors.

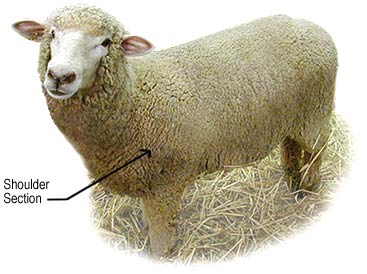

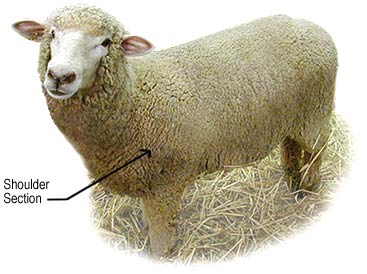

- SPECIAL SECTION OF FLEECE -

- Only the best section of the sheep's fleece is used for each rug.

- The shoulder wool is the longest and the most expensive.

- Shoulder wool gives the rug's pile excellent strength, luster, resilience,

softness and durability. A fine piece of artwork deserves nothing short of the

finest materials

WOOL PROCESSING STEPS: WASHING, SORTING, CARDING, COMBING, SPINNING, PLYING

The CHARACTERISTICS OF WOOL

|

WOOLEN YARN

IS SPUN AFTER CARDING |

WORSTED YARN

IS NOT ONLY CARDED BUT IS GIVEN EXTRA COMBING

TO REMOVE SHORTER FIBERS |

|

'S' and 'Z' TWISTS

SHOW DIRECTION YARN IS SPUN |

THE AMOUNT OF TWIST IN YARN

DETERMINES THE STRENGTH. NO TWIST SHOWS THE FIBERS PARALLEL; THIS IS VERY SOFT WEAK YARN. WITH MORE TWIST IN THE YARN,

IT BECOMES STRONGER AND HARDER. |

|

CROSS SECTION OF A WOOL FIBER

THE MEDULLA IS

FOUND ONLY IN COURSE WOOL. |

SINGLE WOOL FIBER

SHOWING ITS NATURAL CRIMP

WHICH GIVES WOOL ITS WONDERFUL RESILIENCE. |

|

The ADVANTAGES Of WOOL

ENVIRONMENTAL & AESTHETIC CONCERNS

- Wool's structural advantages over synthetics:

- Due to the spring-like properties of the wool fiber,

wool offers greater bulk, density, elasticity, resilience and comfort

and is able to retain its original appearance much longer than other

carpetting materials.

- Wool is naturally both stain and soil resistant - making a wool rug easy to care for.

- Wool's safety advantages over synthetics:

-

The high moisture threshold and moisture-retention rate of wool

fibers provides excellent

natural resistance to flame, combustion and/or ignition.

- Additionally, wool's hydroscopic properties - which allow it to both absorb and release

water vapor without any palpable

wetness - help to modulate extremes in humidity

and also provides natural resistance against static electricity.

- Wool's environmental advantages:

- Wool is anti-bacterial as well as

non-allergenic and non-toxic, and has been used for bedding, clothing and

all types of insulation and floor coverings for thousands of years. It has been documented that the proximity

of wool can actually reduce the human heart rate.

- Quality of Life Issues concerning Wool:

- Wool, especially in a rug or carpet, absorbs sound and dampens echo -

creating greater intimacy and the conditions for more efficient communication.

Even the sound quality of TV and stereo speakers is improved by minimizing reflected

sound waves.

- A wool rug can appreciably absorb the impact

of a fall - thus reducing subsequent injury - especially possible injury to the head.

A child falling on a plush wool surface as compared to a fall on a hardwood or

tile floor surface offers the likelihood of 2 entirely different scenarios.

- Your wool rug is a natural insulator that helps regulate

the effects of extremes in temperature: cooling in Summer, and warming in Winter -

thus contributing to a savings in energy costs.

- Wool carpet has been shown to absorb common pollutants i.e.: formaldehyde,

sulfur dioxide etc., and to prevent their re-introduction into the environment.

This process is ongoing over time and is one of the many inherent properties - and benefits - of wool.

|

COTTON

Although wool is the best material for the rug's pile, it is not a good choice for the foundation

(warp & weft). A rug made with a wool foundation will not lie flat and will be crooked

(especially after washing). Only the nomadic tribes still use wool for foundations, mainly

because they do not own land nor stay in one place long enough to grow cotton. Cotton makes

the best foundation. Silk makes a good warp thread if extreme thinness is desired.

A wool foundation can be recognized by its fringe which is darker and thicker than a cotton

fringe (warp).

|

The ADVANTAGES Of A

COTTON FOUNDATION

- Stronger

- Thinner

- Limited Stretching

- Even Shrinkage

- The Rug Will Keep It's Shape

- The Rug Will Lie Flat

|

DYES

FOUR TYPES OF RUG DYES

|

| NATURAL | ANILINE | ACID | CHROME |

- Oldest

- Color Change

- Fewer Colors

- Inconsistent

- Hard on Wool

- Duller

- Fades in Light

|

- Corrosive

- Colors Faded

- Colors Ran

- Ruined Many Fine Rugs

- (Developed in 1856 - Obsolete)

|

- Cheap

- Colors Run

|

- Resists Acids, Alkalis, Washing & Light

- Won't Harm Wool

- Over 600 Colors

- Colors are Fast

- Won't Run or Streak

- (Developed in 1920's & 30's)

|

Today's synthetic (chrome) dyes are excellent and are not to be confused with the earlier

unsatisfactory synthetic (aniline) dyes of the past.

THE RUG DESIGN PROCESS

|

CARTOON

A cartoon is a full scale graph paper chart which indicates to the weaver the color for

each knot. Every knot is represented by a tiny square. |

TALIM

In some weaving districts

talim cards are used instead of a cartoon. One person reads the color and number of knots to several

weavers. |

|

HOW TO RECOGNIZE A MACHINE MADE 'ORIENTAL DESIGN' RUG

- Machine stitching can always be found along both sides of the rug.

The stitching is normally dyed to make it less noticeable.

- The design is often vague and indistinct.

- The back is covered with perfectly straight lines.

- The fringe is almost always sewn on and not an extension of the warp.

|

THE FINISH DETAILS

VALUE/COLOR PERCEPTION: RUG PILE DIRECTION AND LIGHT REFLECTION

The ADVANTAGES of

CHEMICAL WASH

- Imparts Sheen

- Moth Proofs

- Softens Colors

- Removes Dirt and any Excess Dyes

- Makes Rug more Stain and Soil Resistant

- Removes Loose Fibers

|

Optional Finish Tecniques:

Sculpturing: Carving and incising the rug surface.

|