RUG GUIDE

|

|

| |

| After the wool has been spun into yarn it is dyed. | After being dyed, the yarn is dried slowly in the sun. |

A detailed illustration of the carpet design, most commonly called a cartoon, guides the weavers throughout the entire rug-making process. The design is rendered on graph paper to scale.

|

| A detailed drawing of the carpet's design, which has been rendered to scale

on graph paper, is the weaver's guide throughout the entire weaving process. |

Through the ages, looms have remained relatively unchanged. While the most primitive is the nomadic or horizontal loom, the type most generally used today consists of two vertical beams of either wood or metal and two similarly made horizontal beams. The distance between the vertical beams determines the rug's width. Warp threads, usually cotton, are strung between the horizontal beams at a consistent tension. The thickness of the warp threads and the closeness at which they are strung are two of the elements that will determine the fineness of the weave (i.e., knot density) of the carpet that is ultimately woven.

Turkish/ Symmetrical Knot |

|

Persian/ Asymmetrical Knot |

There are two types of knots used in rug-weaving: the Turkish knot (also called Ghiordes

or symmetrical knot) and the Persian knot (also known as Senneh or asymmetrical knot).

With the average weaver able to tie 10,000 to 14,000 Turkish or Persian knots a day,

several weavers working together can only complete one or two inches of the carpet a

day.

|

| |

| The weaver ties a knot around two adjacent warps, slides it down to the base of the weft and cuts the yarn with a knife. | This procedure of tying and cutting creates the pile of the rug. |

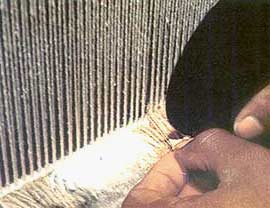

Before the actual knotting of the pile begins, the rug is secured at the bottom of the loom by a short kilim, a flat pileless fabric, which is woven by passing several rows of horizontal cotton threads, or wefts, through alternate warp threads. After rolling the different-colored yarns to be used into balls, the weaver, reading the design from the cartoon begins weaving the rug. With the appropriate color yarn, the weaver ties a knot around two adjacent warps, slides the knot down to the base of the weft, and then cuts the yarn with a knife, thereby producing the pile. After each row of knots is completed, one or more weft threads are inserted to secure the knots and are beaten down tightly with a comb. At this stage, the pile ends are often cut level with a pair of shears. The alternation of wefts with rows of tied knots is repeated until the carpet is finished. Before removing the rug from the loom, another kilim is woven at the top. The fringe is formed by the cutting of the warps at both ends of the rug.

After the rug has been cut off the loom, the final finishing steps take place. First, the

selvedge edges (i.e. side edges of the rug formed by the continuous weft) are bound

or overcast with yarn to reinforce the side edges of the rug. Next, the warp

ends, which secured the rug to the loom, are knotted or braided to form the rug's

fringe. The rug is then washed either by hand or by machine to eliminate dust

and dirt that accumulated during weaving. In addition to cleaning the rug, the

type of wash given the rug can also impart an exquisite sheen and luster to the

wool as well as soften or antique the rug's colors.

|

| |

| After the side edges of the rug are overcast and the fringe has been knotted the rug is washed. | On certain carpets motifs are accented by carving or incising. |

Once the rug is washed and dried, a carpet cutter shears the tops of the knots to create a uniform pile height. In addition to the surface shearing certain carpets feature carved or incised designs which highlight various motifs. Today, this type of accenting is often done to Chinese, Indian, and Turkish carpets. The Oriental rug is now completed and ready for shipment.

Once

the weaving has been completed the rug is cut from the

loom and the surface is sheared to create a

uniform pile height.